Please do not post on this thread, there is a Q&A thread on the same subject

I shall update this thread as work progeresses

Thig guide is to provide help & support relating to retro fitting aforementioned bumpers, and suppliers. I do not supply or sell, supplier details will follow, this is presently work in progress. Acknowledgements will also be added to the thread.

all parts will be available from

http://www.autogpsdvds.com/

as and when they become available and tested for suitability.

Rover premium bumper

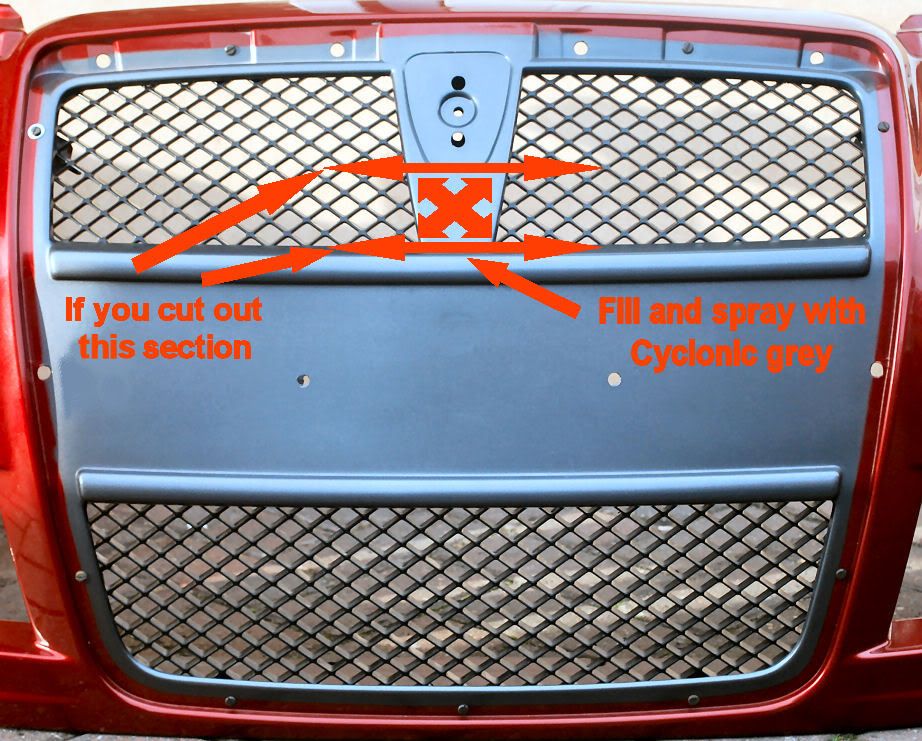

This section relates to fitting a MG7 grill and chrome surround to a Rover premium bumper, obtaining the parts, and the tools used

Premium bumper

Bare premium bumper

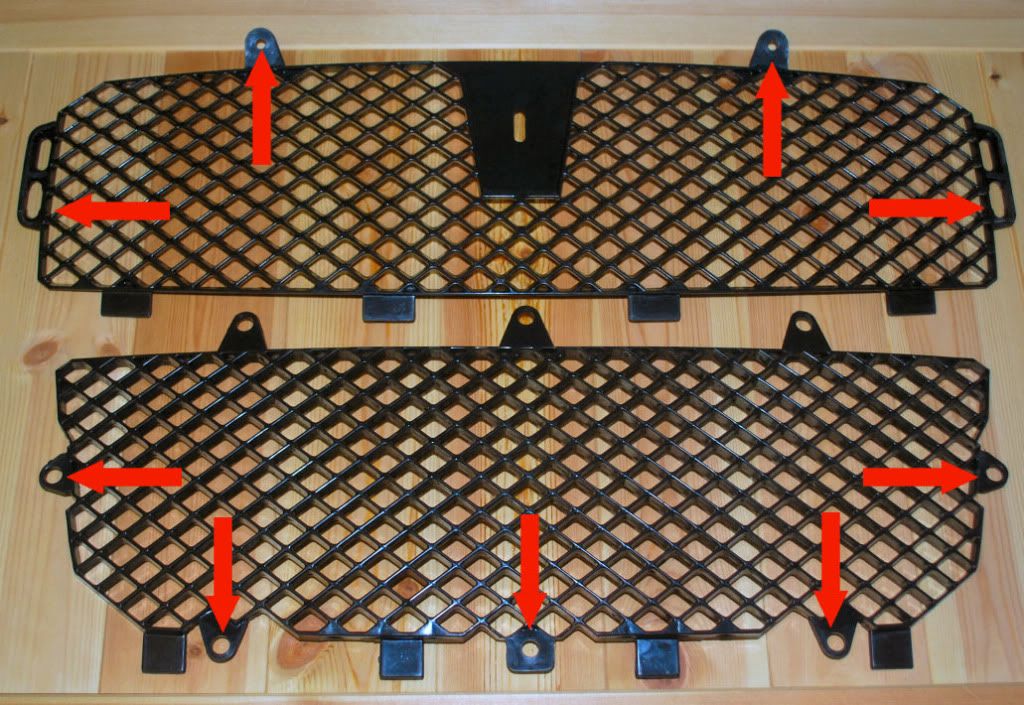

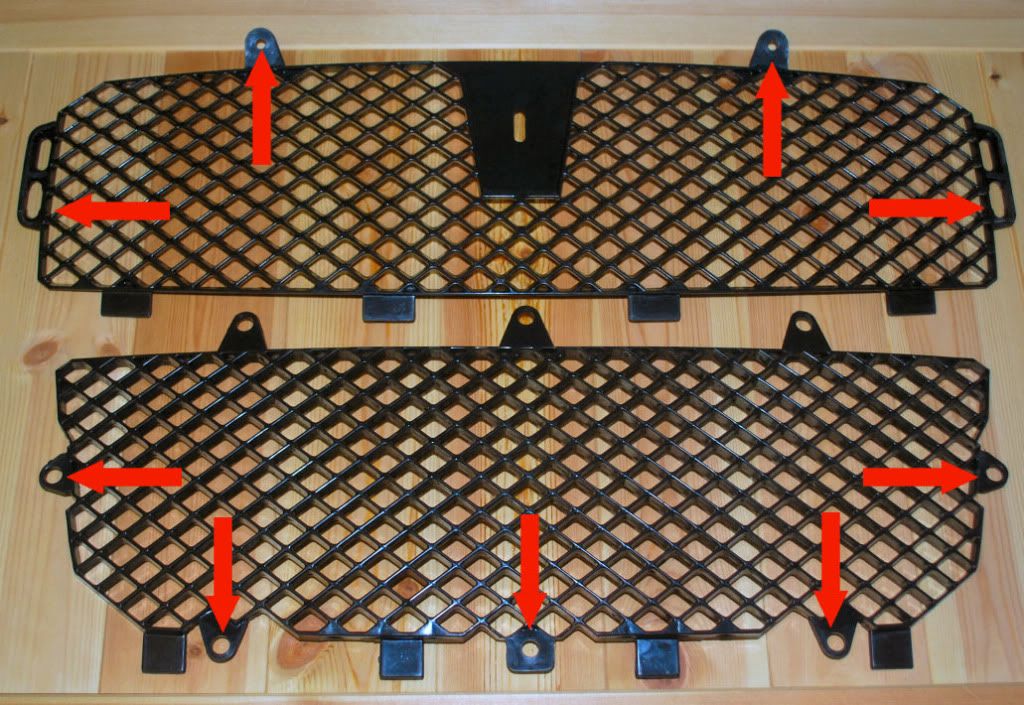

MG7 grille, 4 bolts fix the upper grille, 5 bolts lower grille. M4 panhead brass nuts & bolts are used

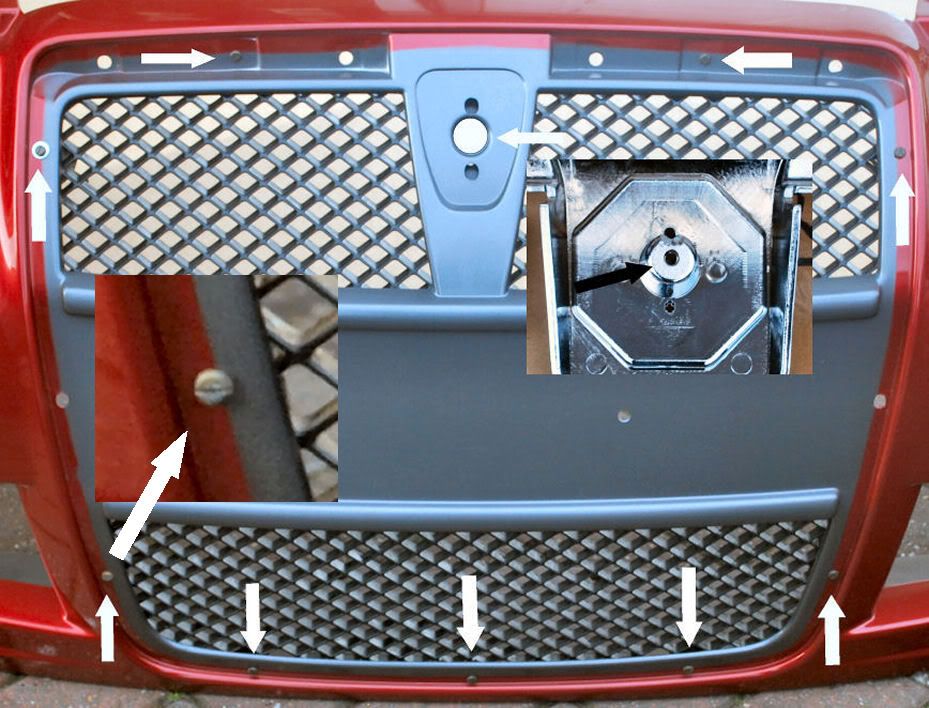

Bare premium bumper with MG7 grille and plug n play MkII indicators

Rear view

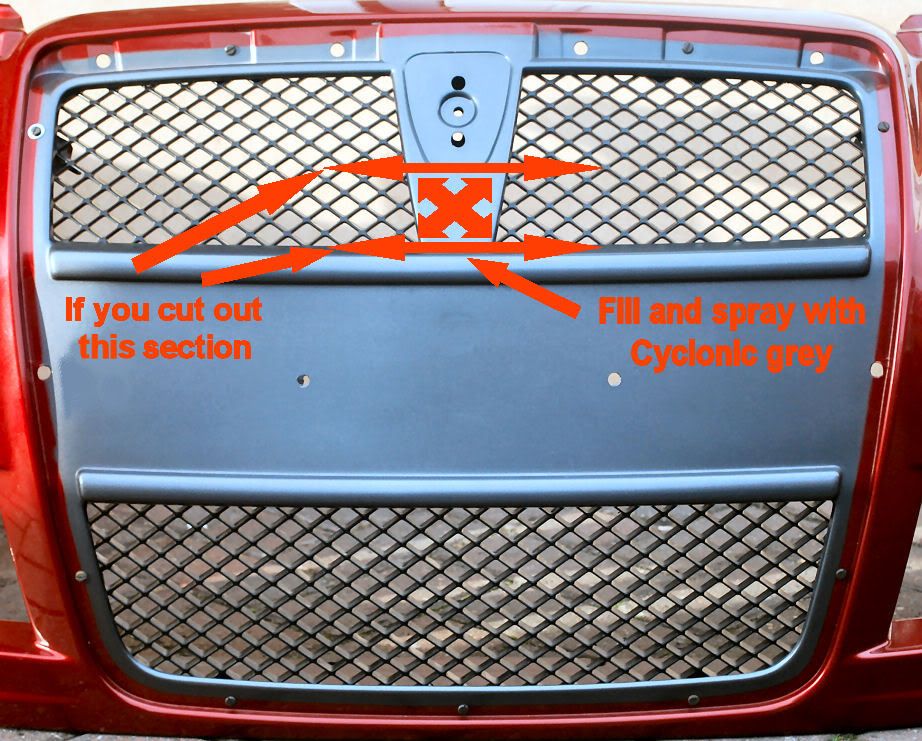

Bolt holes 'arrowed', had to be drilled for the brass nuts & bolts used to attach the grilles.

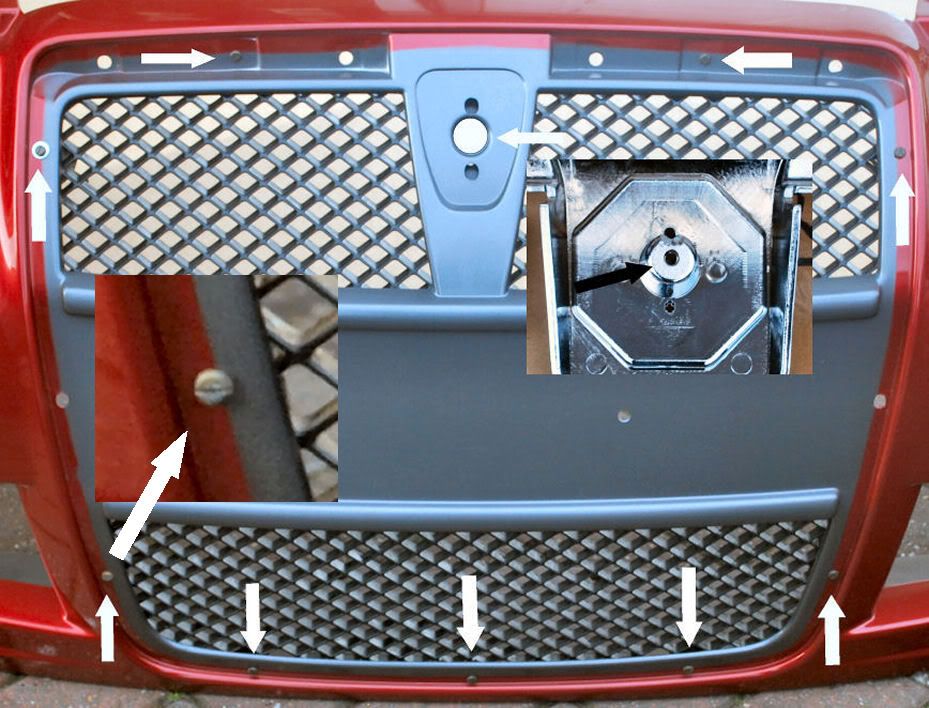

Be mindfull that the groove at the back of the chrome surround along the bottom and sides, has to straddle the bolt head (insert). A hole cutter was used to cut a hole in the bumper badge mount to accomodate the hollow on the rear of the MG7 chrome surround badge recess. (insert)

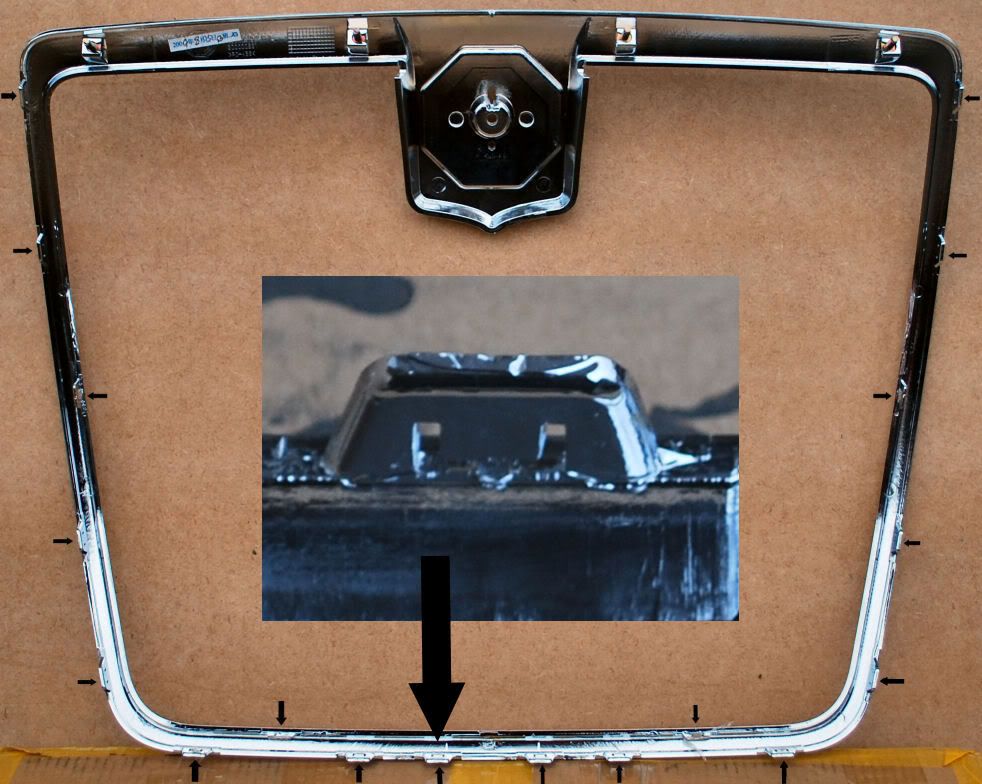

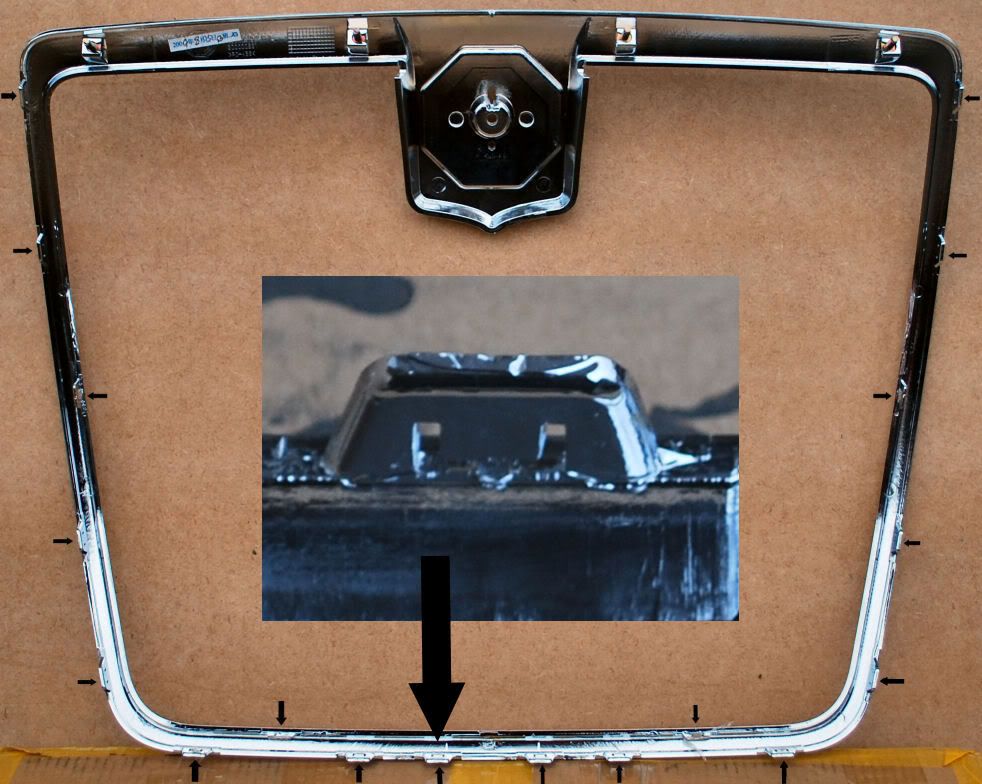

MG7 chrome surround

Rear view, notice the MG7 chrome surround is in one piece , eliminating the chrome facia detaching from its inner mount

The MG7 chrome surround is secured to the bumper by bolts across the top that match the holes in the top of the premium bumper. The sides and bottom are held in place by barbed blades that push into slots in the MG7 bumper.(insert)

Slots matching the blades on the rear of the MG7 chrome surround need to be cut into the premium bumper.

My choice of weapon is the Dremel with 1mm X 25mm or 1mm X 30mm cutting discs. I used a 0.5mm sanding disc sandwiched beteen two 1mm X 25mm cutting discs. This allowed me to widen the slot in either direction without making it too wide.

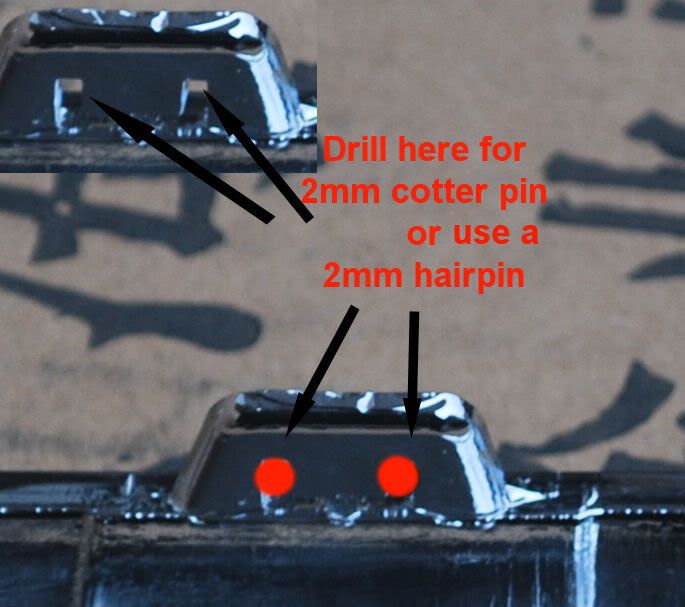

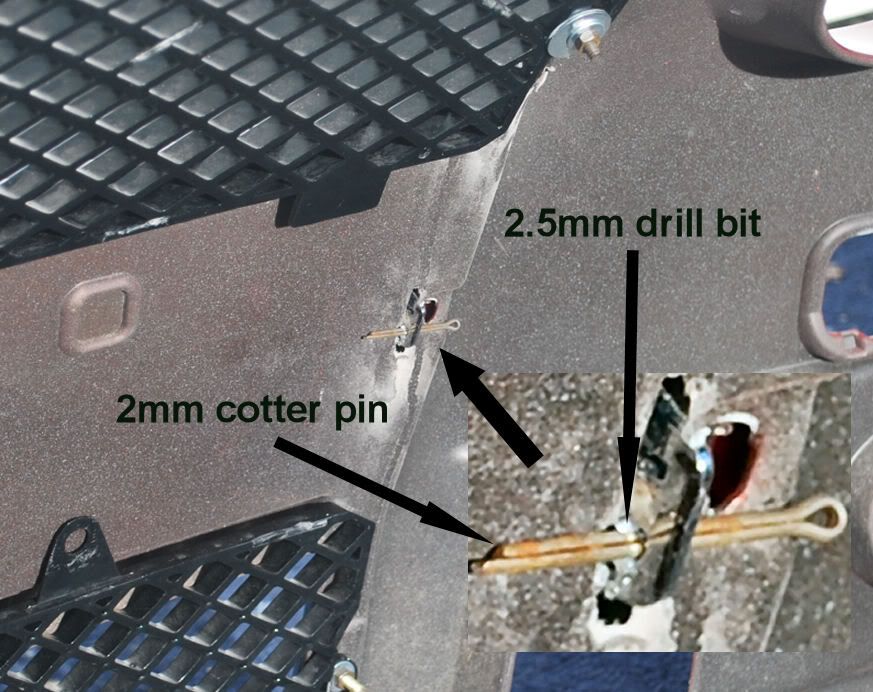

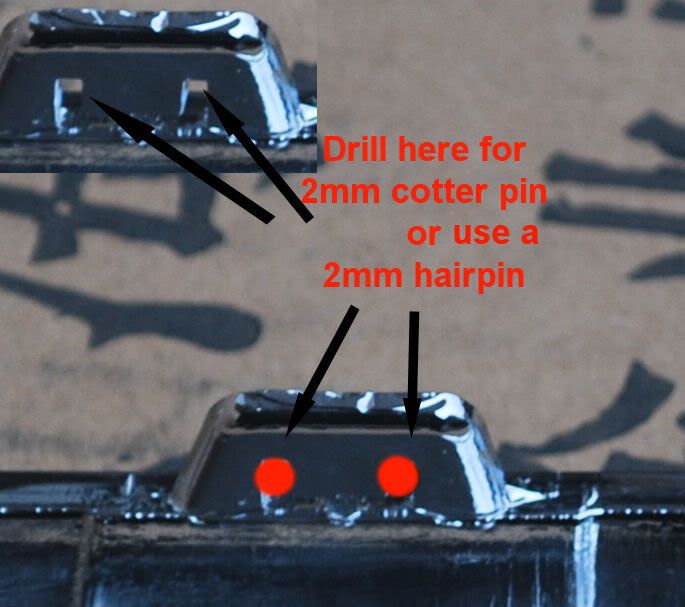

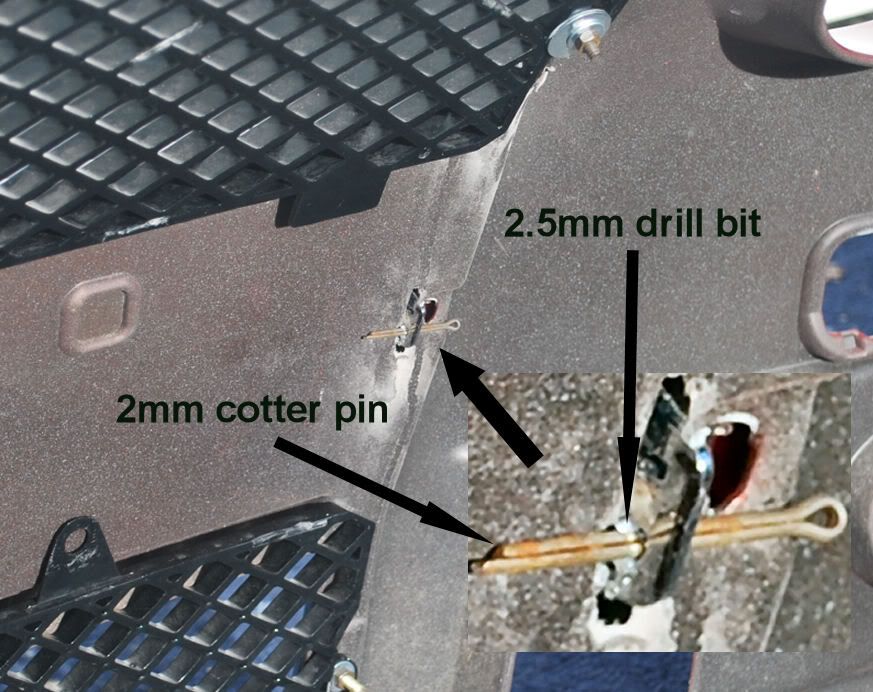

You may well find as I did, that some slots may need widening to a point where the blade on the surround is a loose fit. This did not bother me too much because I figured to use additional securing methods to prevent the surround from popping off. The best method I found, was each barbed blade has a U shaped slot suitable for hairpin type cotter pins, or 1 or 2 holes can be drilled to widen the slot to accomodate 2mm cotter pins.

The first MG7 grille and chrome surround retro fit are complete and it looks pretty good.Fitting is far from a simple task. Slots have to be cut into the bumper to fit the chrome surround, anyone who thinks they can glue it so it will not become detached through a nice cold winter do so at their own risk. This also means that should the need for the surround to be removed arise, then it is a case of a new surround.

The numberplate and badges are a photoshop job, the chrome surround is not pushed fully home yet.

My preference is to use harpins and cotters on all the blades, making the slots wide enough not to need a screwdriver to start levering off the surround should the need arise.

If you fancy doing this

Then you can have this

Smart or what

Trebor is looking to get octagonal Rover badge manufactured to fit the MG7 badge recess, he has posted much info if you search

Hopefully it will fit ok, the profile appears to be the same

MG7 bumper and Roewe 750 bumper is also in progress, unfortunately it is not like popping to Halfords

2008 Roewe 750

I shall update this thread as work progeresses

Thig guide is to provide help & support relating to retro fitting aforementioned bumpers, and suppliers. I do not supply or sell, supplier details will follow, this is presently work in progress. Acknowledgements will also be added to the thread.

all parts will be available from

http://www.autogpsdvds.com/

as and when they become available and tested for suitability.

Rover premium bumper

This section relates to fitting a MG7 grill and chrome surround to a Rover premium bumper, obtaining the parts, and the tools used

Premium bumper

Bare premium bumper

MG7 grille, 4 bolts fix the upper grille, 5 bolts lower grille. M4 panhead brass nuts & bolts are used

Bare premium bumper with MG7 grille and plug n play MkII indicators

Rear view

Bolt holes 'arrowed', had to be drilled for the brass nuts & bolts used to attach the grilles.

Be mindfull that the groove at the back of the chrome surround along the bottom and sides, has to straddle the bolt head (insert). A hole cutter was used to cut a hole in the bumper badge mount to accomodate the hollow on the rear of the MG7 chrome surround badge recess. (insert)

MG7 chrome surround

Rear view, notice the MG7 chrome surround is in one piece , eliminating the chrome facia detaching from its inner mount

The MG7 chrome surround is secured to the bumper by bolts across the top that match the holes in the top of the premium bumper. The sides and bottom are held in place by barbed blades that push into slots in the MG7 bumper.(insert)

Slots matching the blades on the rear of the MG7 chrome surround need to be cut into the premium bumper.

My choice of weapon is the Dremel with 1mm X 25mm or 1mm X 30mm cutting discs. I used a 0.5mm sanding disc sandwiched beteen two 1mm X 25mm cutting discs. This allowed me to widen the slot in either direction without making it too wide.

You may well find as I did, that some slots may need widening to a point where the blade on the surround is a loose fit. This did not bother me too much because I figured to use additional securing methods to prevent the surround from popping off. The best method I found, was each barbed blade has a U shaped slot suitable for hairpin type cotter pins, or 1 or 2 holes can be drilled to widen the slot to accomodate 2mm cotter pins.

The first MG7 grille and chrome surround retro fit are complete and it looks pretty good.Fitting is far from a simple task. Slots have to be cut into the bumper to fit the chrome surround, anyone who thinks they can glue it so it will not become detached through a nice cold winter do so at their own risk. This also means that should the need for the surround to be removed arise, then it is a case of a new surround.

The numberplate and badges are a photoshop job, the chrome surround is not pushed fully home yet.

My preference is to use harpins and cotters on all the blades, making the slots wide enough not to need a screwdriver to start levering off the surround should the need arise.

If you fancy doing this

Then you can have this

Smart or what

Trebor is looking to get octagonal Rover badge manufactured to fit the MG7 badge recess, he has posted much info if you search

Hopefully it will fit ok, the profile appears to be the same

MG7 bumper and Roewe 750 bumper is also in progress, unfortunately it is not like popping to Halfords

2008 Roewe 750

If at first you don't succeed, hide the evidence.