Sure I replied to these! I've got to start making sure I click submit instead of preview!

Bernard wrote:Solvent welded acrylic is certainly weather proof but is easily cracked.

I've constructed fluid tanks in that manner.

If the cables are brought in through waterproof glands vertically through the bottom panel, I would have thought they will be OK. Better still they could be sealed with gutta-percha or similar.That would then stand occasional immersion.

If solvent weld cracks easily then I think this would be a bad choice as the panel is going to be a sort of display piece, hence the vision panel and backlighting. I could incorporate a box within a box though that would prevent knocks and bumps, I think this may work out at the cheapest option so far. Cheers Bernard

Xpart02 wrote:Monk wrote:Afternoon all,

Does anyone have any experience of building waterproof housings for electronics? I am making a panel up to be situated outside, which will have a glass/lexan sheet window to show off the boards. There are approximately 2500 1mm cables entering this panel as well as 10 USB cables and 10 power cables. There are 10 PCBs housed in the panel, to be mounted on an aluminium frame which is backlit.

What is an extremely neat, but cheapish method to waterproof something?? If I built the entire box from acrylic and solvent welded the parts together, is this sufficient to weather proof? Any ideas how to make the back removeable but retain the weatherproofing?? With regards to the cables, the USB and Power I can use cable gromets, but the small matter of 2500 1mm cables is proving a nightmare. Would bundling these through 25mm conduit, bunging the end with a clay, and filling with epoxy resin be sufficient. I can make that look nice, but any other ideas?

Many Thanks

Hi,

I used to design industrial switchboards years ago,

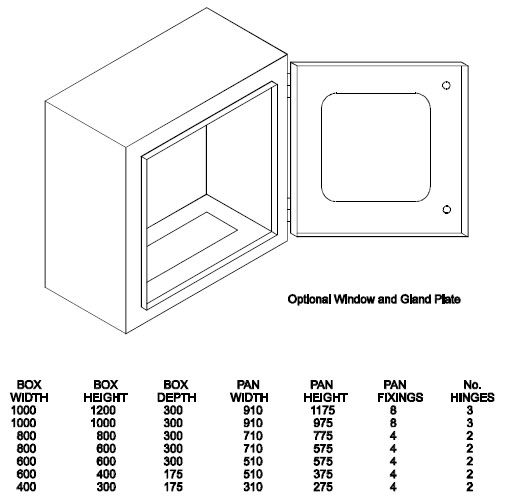

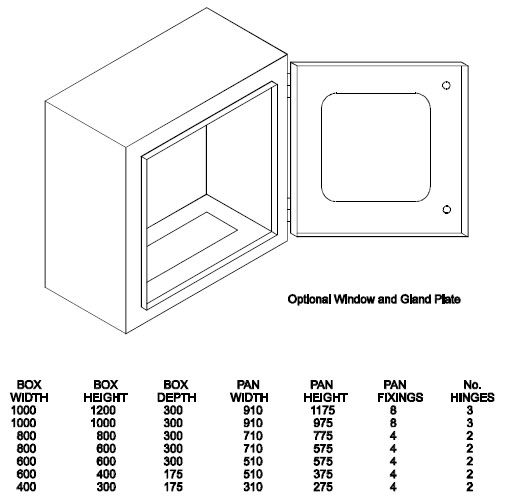

Sounds like you need an IP55 or 65 rating DB. ( Distribution Board).

The door panel could be cut out to accept a clear panel. Some of ours used to be like that anyway.

Can you find a disused DB and modify it?

something along these lines?

They are all ones I have designed in the past.

Feasible if I could find one I guess, are they easy to find 2nd hand? Will have to scour ebay later! Cheers!

Duncan wrote:Very tricky to make them 100% dry. Changes in temperature and air pressure can get stuff past seals.

To allow for breathing, you can get a gland with fabric in it, something like goretex which allows breathing. It means your seals have to work a lot less hard.

Oh, and make sure all the cables enter / exit at the bottom, then gravity is with you, not against you.

Cheers Duncan, are the glands called anything specific to search for, or just a case of doing a bit of simple mans explanation search!?