There are connectors about known as Scotchlocks. Personally I don't like these because there is a risk they will dmage the existing wiring, and if used outside the car promote water getting under the sleeving and causing corrosion.

As I was doing some work today which involved rewiring the towing electrics on one of my cars I thought I'd share some pictures.

1. The damage caused to one of the cars wires by a scotchlock. They don't always do this but you have to get the correct size for the wire if you don't want it to do this. And how many places sell a variety of sizes?

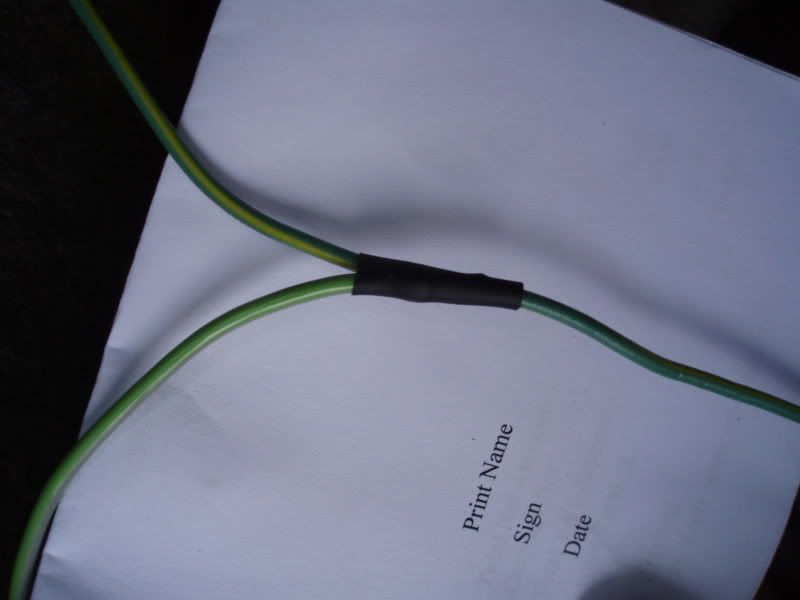

2. My preffered method. The splice provides the electrical connection but also gives some support to the wire. If you strip a harness down, you will find many similar splices inside it.

3. Heatshrink sleeving. Additional support as well as insulation. In a damper environment I would use adhesive lined heatshrink, but it's best to make the splice in a dry area.

Nice info in the wiring but why would you have to sign, print and date it :

Nice info in the wiring but why would you have to sign, print and date it :